FIBBI ELIO

A dynamic, reliable, and experienced team equipped with the best tools for the production of systems and machinery in thermoplastic material.

services

At the service of companies that

need thermoplastic components to complete their business.

CLIENTS

Fibbi Elio’s clients operate in various technical sectors of the chemical, goldsmith, electroplating industries and many other fields.

Over more than 50 years of activity, Fibbi Elio Srl has developed a wide range of products, the result of internal design work and expertise acquired over time.

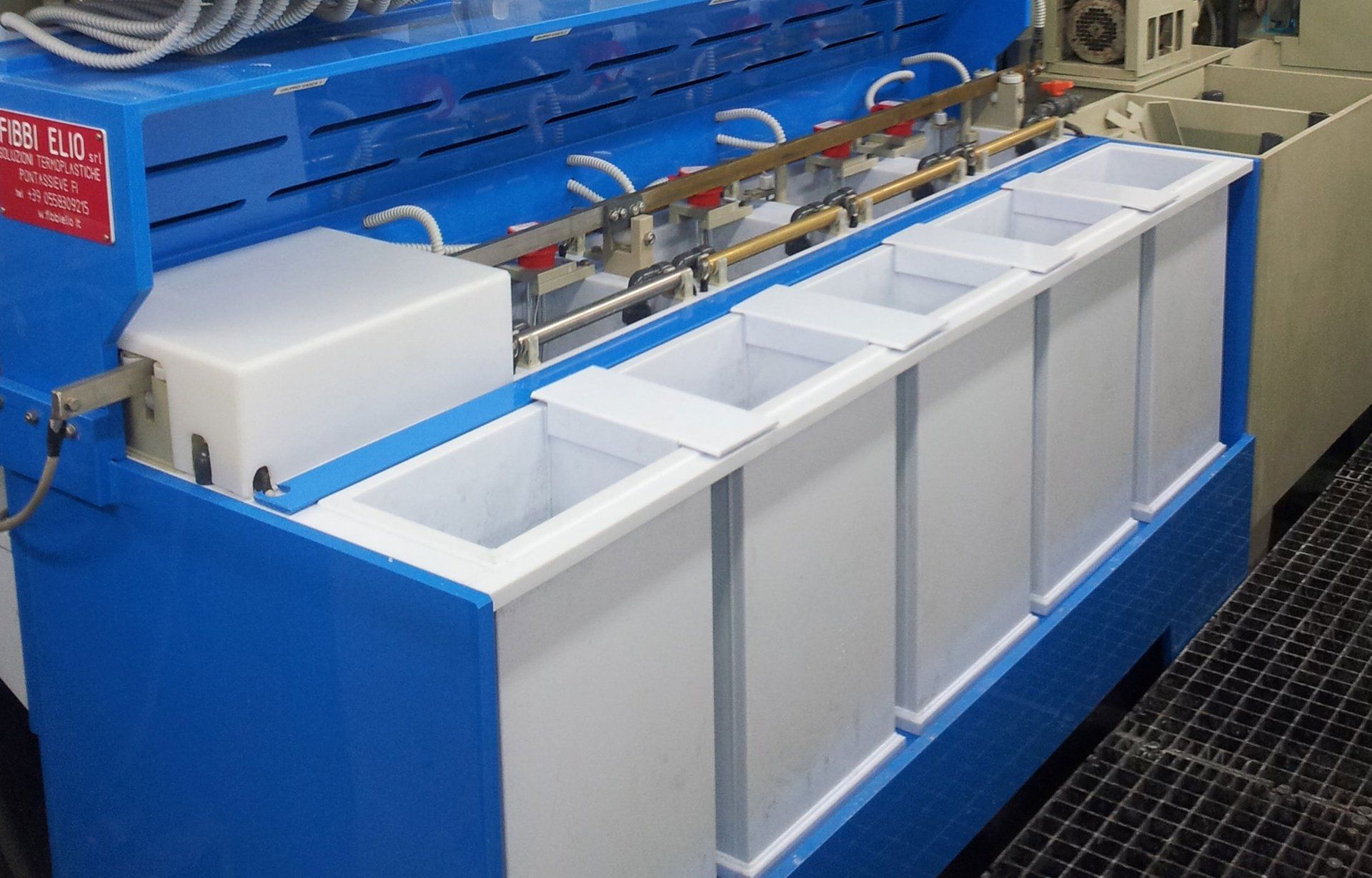

Specifically, the company based in Pontassieve specialises in producing the following systems:

- machines for frosting and polishing glass;

- complete systems for the extraction and treatment of acidic fumes (scrubbing towers);

- systems for wastewater treatment.

In addition to design, the company also handles machinery installation and start-up, as well as staff training, by providing highly specialised internal technical personnel.

PROJECTS

The staff of Fibbi Elio in Pontassieve works alongside industries in various sectors. In particular, in the environmental sector, the company produces machines for frosting and polishing glass, systems for extracting and treating acidic fumes (i.e., scrubbing towers), and complete systems for wastewater treatment.

In addition to handling the design, the company provides full support for machinery installation and start-up, offering a team of specialists who are also ready to train the client company's personnel.

Fibbi Elio’s clients range from those in the glass processing sector to the chemical, electroplating, and goldsmith industries: for more details and quote requests, don’t hesitate to contact the office using the contact details provided.

PROFESSIONAL TECHNICIANS, MODERN MACHINERY, AND FIRST-RATE MATERIALS

To ensure the production and final quality of its systems, Fibbi Elio Srl uses specialised and qualified technical personnel and technologically advanced production machinery such as:

automatic saws for cutting parts,

automatic welding machines (welds certified to DVS 2207 standards, with documentation provided),

automatic benders for uniform shaping of parts.

The company also pays careful attention to raw materials, which are selected with great care to always ensure the highest quality of the final product, choosing components and equipment mounted on the systems that are suitable for optimising performance, increasing reliability, and extending service life.

CUSTOM PROJECTS BASED ON CLIENT SPECIFICATIONS

The main part of the company’s production focuses on custom projects based on client specifications, for various applications in the chemical, electroplating, goldsmith, or other sectors with harsh environments.